ILAS 3000

Technical Specifications*

| Capacity/Speed | Up to 600 samples/hour Up to 480 samples + 24 pilot samples at the same time Approximately 10 minutes from sample loading to the first analytical result |

| Drawer size (WxDxH) | Max 419 x 666 x 78 mm |

| Vials size (HxW) | Min 78 x 27 mm – Max 115 x 32 mm Other types of vials subject to adaptations |

| Scanning of samples | Optional barcode RFID chips (LF 125 kHz, 134 kHz FDX and HDX, HF 13.56 MHz) |

| Compressed air supply | > 6 bar, clean and oil-free |

| Air consumption | Average 25 L/mn, peak 50 L/mn |

| Voltage | 220-240 VAC ±10% | 50-60 Hz |

| Power consumption | Max 2400 VA |

| Ambient temperature/humidity | 15-33°C < 93% HR |

| Dimensions (WxDxH) | 1250 x 1850 x 1300 mm (screen not included) |

| Weight | 650 kg comprising a complete water bath and a full load of samples |

| Standards | ILAS 3000 is CE certified according to the Machine Safety, Low Voltage and EMC Directive. |

*Specifications subject to change without notice.

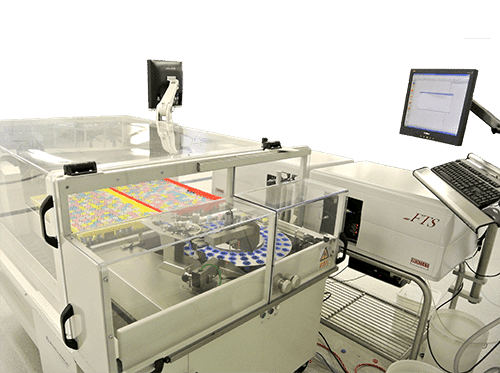

Efficient processing of each sample

Sample handling in your laboratory is revolutionized by the use of the ILAS 3000.

The unit automates all samples handling procedures:

- Samples are identified and transferred from the tray to the samples carousel,

- Samples are heated to the desired temperature, immersed in a water bath regulated at a stable temperature while rotating in a carousel,

- The automated system mixes the samples prior to analysis to allow the analyzer to take a representative sample,

- The samples are decapped,

- Samples are identified by barcode or RFID reading (optional),

- Samples are presented to the analyzer stirrer/pipette,

- Samples are returned to their original tray position,

- Control samples are inserted in samples stream automatically and analyzed as required.

Added value and benefits

Efficiency

The ILAS 3000 is very simple to use. The robot can perform all manual and monotonous work efficiently, allowing users to dedicate themselves to other activities. As a result, laboratory performance is increased. Operator training is simplified since most activities are performed automatically by the robot.

Cost savings

A single operator can manage up to three CombiFTS lines. Simply prepare the sample trays and remove them from the robot at the end of the analysis.

Quality assurance

All automated procedures are highly repeatable, ensuring robust and reliable measurements.

The pilot samples are placed in a separate compartment. Depending on the needs of the laboratory, these pilot samples can be automatically inserted into the current analysis sequence to check the stability of the instrument. Depending on the level of integration of the instrument, the ILAS 3000 can automatically alert the operator in case of abnormal results. In this case, automatic re-analysis of the samples is possible.

Productivity

Each robot has two drawers to hold the sample trays and therefore allows continuous activity. While the robot takes care of the first drawer, the operator has free access to the next one. The robot can operate at a speed of up to 600 samples per hour, depending on the analyzer.

Reliability

The ILAS 3000 is renowned for its longevity, with some units having been in continuous operation for more than 15 years..

A tailor-made customization for your laboratory

Trays

The supports used inside the drawers of the ILAS 3000 are customizable, in order to meet your needs with an optimal solution.

If you are considering the possibility of automating your entire laboratory, the tray design and work procedures need to be reviewed and we will provide you with a complete and fully customized solution, with all the necessary support.

Vials

ILAS 3000 can be adapted to handle most commonly used vials.

Grouping of tasks

The ILAS 3000 is designed to direct one customer task after another to the analyzer. Multiple customer tasks can be loaded into the automat but must be processed in turn. The trays are automatically indexed to allow recognition of the type of sampling. Sampling rules are required to confirm the limits of the tasks within a tray.

Modular and customizable integration

The ILAS 3000 robot offers two main types of integration with the analysis unit:

- In “Basic Integration” mode, the ILAS 3000 acts as a sample presentation automaton, leaving the analyzer to manage client tasks and the LIMS connection,

- In “Total Task Integration” mode, the ILAS 3000 can manage other aspects related to analysis quality, LIMS connection and simplify the operator’s user experience.

The ILAS 3000 is fully integrated with Bentley Instruments’ FTS/FCM and alternative methods.

Technical Specifications*

| Capacity/Speed | Up to 600 samples/hour Up to 480 samples + 24 pilot samples at the same time Approximately 10 minutes from sample loading to the first analytical result |

| Drawer size (WxDxH) | Max 419 x 666 x 78 mm |

| Vials size (HxW) | Min 78 x 27 mm – Max 115 x 32 mm Other types of vials subject to adaptations |

| Scanning of samples | Optional barcode RFID chips (LF 125 kHz, 134 kHz FDX and HDX, HF 13.56 MHz) |

| Compressed air supply | > 6 bar, clean and oil-free |

| Air consumption | Average 25 L/mn, peak 50 L/mn |

| Voltage | 220-240 VAC ±10% | 50-60 Hz |

| Power consumption | Max 2400 VA |

| Ambient temperature/humidity | 15-33°C < 93% HR |

| Dimensions (WxDxH) | 1250 x 1850 x 1300 mm (screen not included) |

| Weight | 650 kg comprising a complete water bath and a full load of samples |

| Standards | ILAS 3000 is CE certified according to the Machine Safety, Low Voltage and EMC Directive. |

*Specifications subject to change without notice.

ÚDRŽBA A PODPORA

Služba zákazníkům vždy byla prioritou společnosti Bentley Instruments. Zaručujeme našim zákazníkům promptní pomoc pro optimální produktivitu.

Abychom zaručili nejvyšší úroveň produktivity, náš tým techniků se stará o instalaci, školení a diagnostiku vzdáleně i lokálně.

Platforma FreshDesk je k dispozici po registraci a poskytuje přístup k naší e-službě.

E-ticketová služba umožňuje položit našim inženýrům dotazy ohledně vašich problémů, technické databáze (historie zařízení, technické poznámky, manuály...), diagnostické nástroje (problém/řešení), celosvětovou síť výrobních inženýrů a servis po prodeji pro rychlou a interaktivní pomoc, která je k dispozici kdykoli.